Biomass carbonization is a thermal decomposition process conducted under limited oxygen conditions to convert organic materials into carbon-rich substances. This method has gained widespread attention as a sustainable approach to waste management and energy recovery. Various types of biomass, including agricultural residues, wood, and shells, can be used to produce biochar — a stable, carbon-rich material with multiple applications.

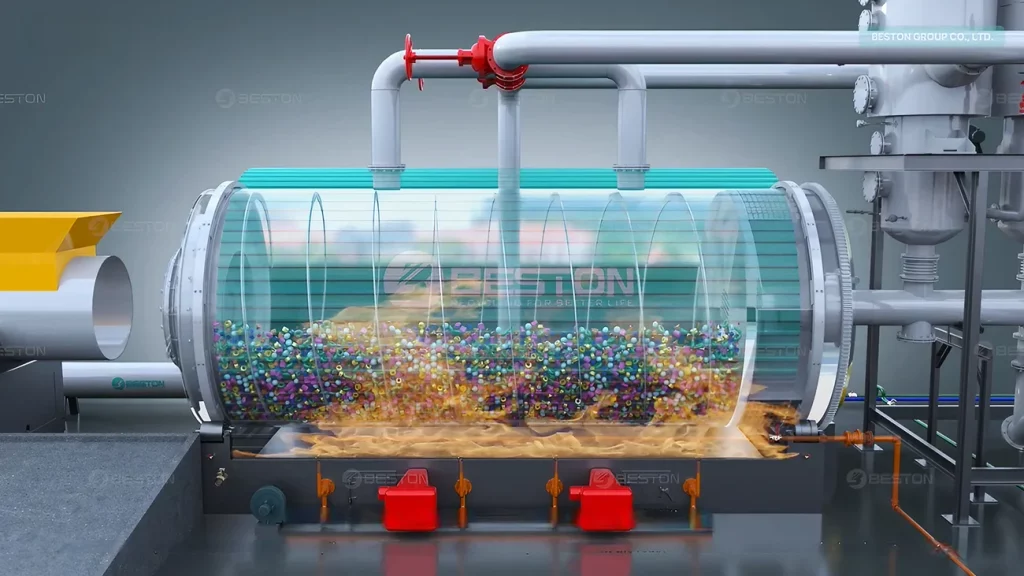

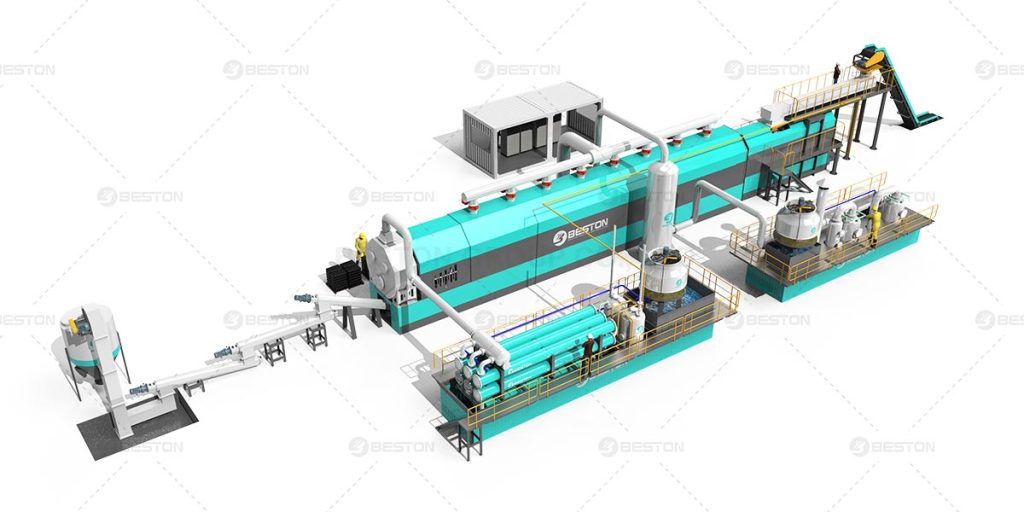

A key component in this process is the use of a specialized carbonization machine, which ensures the right environment, temperature, and residence time for optimal conversion.

Importance of Temperature in the Carbonization Process

Temperature plays a pivotal role in biomass carbonization. The process typically begins at around 200°C and can reach up to 700°C, depending on the desired quality and characteristics of the resulting biochar. The carbonization pathway involves several stages: drying, pyrolysis, and carbon formation. Each stage corresponds to a specific temperature range that influences the chemical structure of the biomass.

For instance, at 200–300°C, moisture and volatile compounds begin to evaporate. As the temperature increases to 400–500°C, hemicellulose and cellulose decompose rapidly, releasing flammable gases and leaving behind a solid carbon residue. Above 500°C, lignin undergoes deeper transformation, and the biochar becomes more porous and carbon-dense.

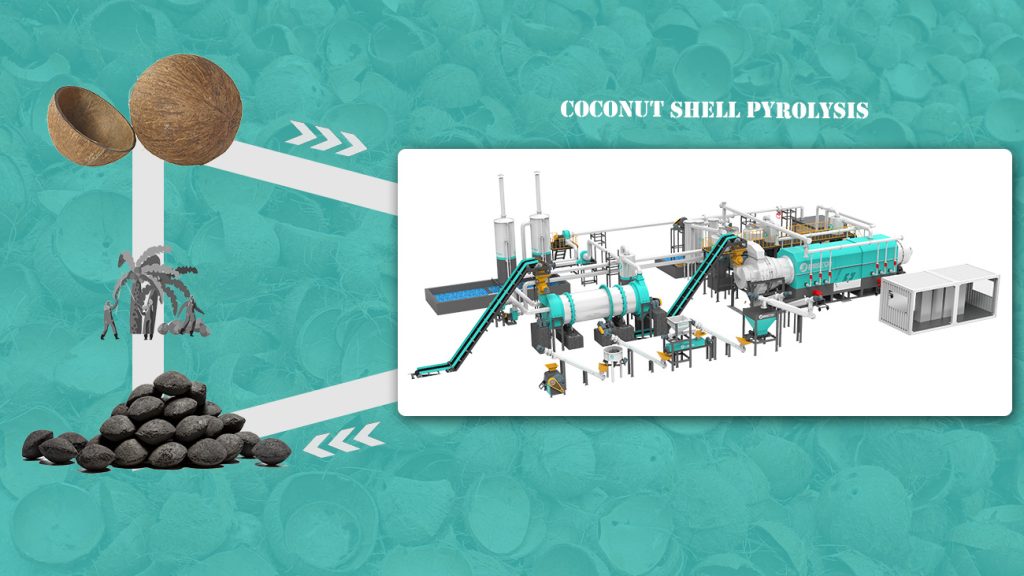

In applications like coconut shell charcoal making machine, the temperature control must be precise to ensure high calorific value and fixed carbon content in the final product.

How Time Affects Carbonization Output

Time, alongside temperature, is a crucial factor in determining the efficiency and quality of biochar. The total duration of the carbonization process can range from 30 minutes to several hours, depending on the type of biomass and the heating rate.

A slow heating rate usually favors the formation of more solid biochar, whereas rapid heating can increase gas and liquid yields but reduce solid residue. Prolonged residence time allows more thorough thermal decomposition and leads to higher carbon content. However, excessively long carbonization can result in energy inefficiency and lower yield due to over-oxidation or secondary reactions.

Modern systems like the wood charcoal making machine are equipped with smart control units that regulate time and temperature simultaneously to achieve consistent biochar quality.

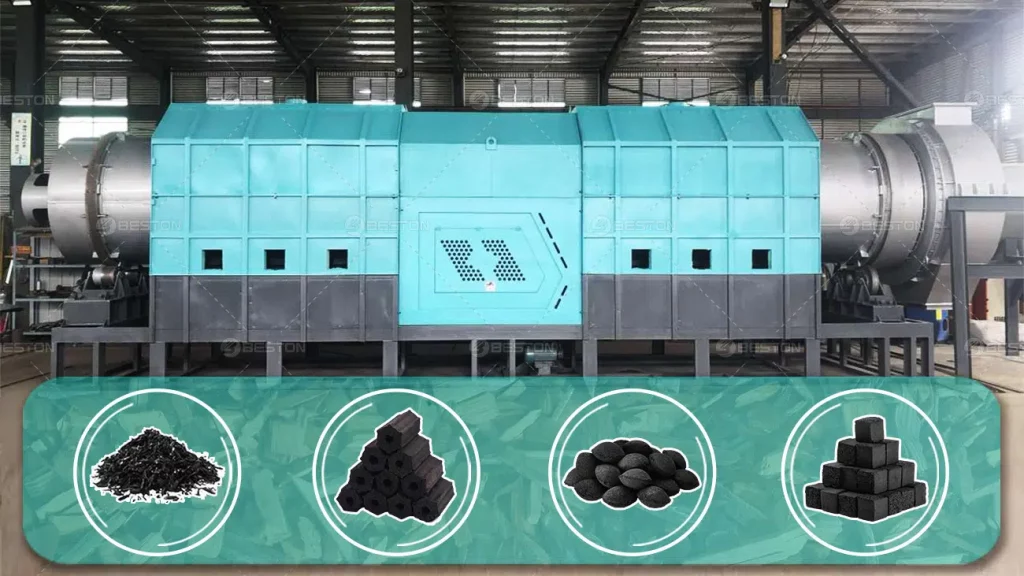

Biochar as the Main Product

The main product of biomass carbonization is biochar — a stable, porous, and carbon-rich solid. Biochar has numerous applications, especially in agriculture, where it improves soil fertility, water retention, and microbial activity. It also serves as a carbon sink, playing a role in climate change mitigation.

The properties of biochar, including surface area, pore structure, and carbon content, depend heavily on both the type of feedstock and the parameters of the carbonization process. For example, using a straw charcoal machine may yield biochar with higher silica content, which can benefit specific soil types.

Biochar can also be used as a filtration medium, an additive in construction materials, and a fuel substitute. Its high thermal stability and low reactivity make it a valuable commodity across industries.

Feedstock Selection and Its Influence

Different biomass feedstocks yield biochar with varying qualities. Common materials include coconut shells, wood chips, rice husks, corn stalks, and straw. Each feedstock has unique structural and chemical characteristics that influence the decomposition pathway and the final biochar composition.

Coconut shells, for instance, have high lignin content, making them ideal for producing dense and high-quality charcoal. When processed using a dedicated coconut shell charcoal making machine, the result is a product with superior heating value and longer burning time, ideal for industrial fuel or BBQ applications.

Wood biomass, on the other hand, offers more uniform carbonization behavior and consistent biochar quality. A wood charcoal making machine is commonly used in large-scale production for bioenergy purposes.

Technological Advancements in Carbonization

Traditional methods of charcoal production, such as open-pit burning or kilns, are often inefficient and environmentally harmful. Today, the development of advanced carbonization equipment has revolutionized the industry. These systems offer higher thermal efficiency, reduced emissions, and automated control.

A modern carbonization machine is designed to operate under a continuous or batch system. It includes features such as heat recovery, smoke purification, and digital monitoring, making the process cleaner and more efficient.

Moreover, these machines are adaptable to various feedstocks, enabling producers to switch materials depending on availability and market demand.

Environmental and Economic Benefits

Biomass carbonization is not just an effective waste-to-resource strategy—it’s also environmentally beneficial. The biochar produced sequesters carbon that would otherwise be released into the atmosphere through decomposition or burning. This contributes to the reduction of greenhouse gases and promotes circular economy practices.

From an economic perspective, the demand for biochar is rising globally. It is being recognized for its potential in organic farming, green construction, and even carbon trading markets. Entrepreneurs and governments alike are investing in technologies like the straw charcoal machine to tap into this growing market.

Conclusion

Biomass carbonization is a sophisticated process that hinges on the control of temperature and time to yield valuable biochar. The type of biomass, machine efficiency, and process parameters all play a role in determining the quality and yield of the final product. With the aid of modern equipment such as the wood charcoal making machine and coconut shell charcoal making machine, producers can achieve high efficiency and minimal environmental impact. As industries look toward greener solutions, biochar production through carbonization offers a practical and profitable path forward.